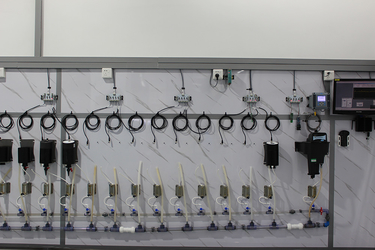

Our factory is located at Room 301, Building 3, No. 25 Datong Road, High-tech Zone, Suzhou City, JIANGSU P.R CHINA. We have laboratories, warehouses and workshops for instrument production. We have professional workers for production, and we also equip the instrument with related workshops for debugging, aging test, filming, welding, etc. The company's workers have many years of work experience, and will conduct a unified quality inspection after the production is completed.

Production main workflow:

1. Understand market demand and customer needs, and determine product functions and performance indicators.

2. Develop production plans and quality control standards and check the work instructions

3. Make ingredients list, store ingredients for ingredients, quality control for delivery and inspection;

4. Workers perform preliminary installation, including substrates and accessories;

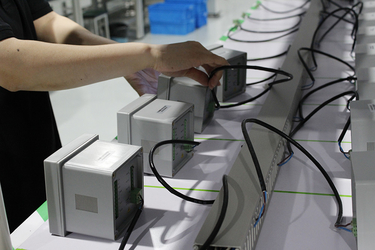

Assembly: Assemble the components into a complete machine.

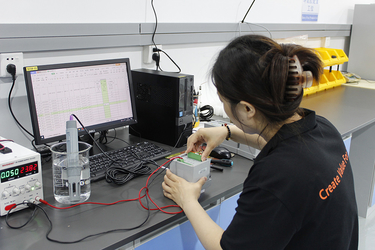

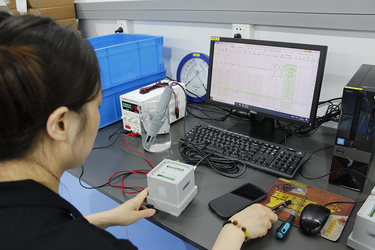

Testing: Perform strict performance and reliability tests on the product.

5. Software engineering, including software burning;

Debugging: Debug the assembled product to ensure that it functions properly.

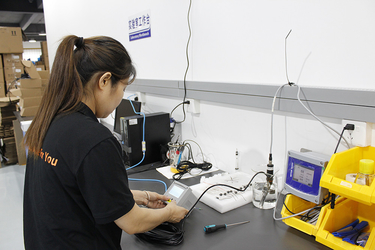

6. Calibration: data recording;

7. The quality control department conducts individual instrument testing and online testing, and power-on aging inspection;

Factory inspection: Inspect the purchased raw materials.

Production process inspection: Sampling inspection during the production process to ensure that the product meets the standards.

8. The assembly department conducts the assembly of the whole machine and the labeling of the fuselage;

9. The quality control department conducts power-on testing and functional testing;

Factory inspection: Final inspection of the finished product to ensure product quality.

Sample all functional inspections.

10. Visual inspection;

11.Packaging and delivery:

Packaging of quality-inspected products to prevent damage during transportation.

Arrangement of logistics to deliver products to customers or distributors.

12.After-sales service:

Provide product training and technical support.

Handle customer feedback and after-sales service issues.

13.Continuous improvement:

Continuously improve product performance and functionality based on market feedback and technological development.

Development of new technologies and new products.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!